Applications OSBs

Can I use

an Orbital Shaken Bioreactor for My Application?

In orbital shaken bioreactors (OSBs), efficient mixing and sufficient oxygen supply are ensured by the orbital movement along with bubble-free surface aeration. This eliminates the need for agitators and spargers resulting in lower shear forces, making this technology ideal for shear-sensitive cells. Additionally, OSBs use disposable 3D bags, reducing the risk of contamination, simplifying cleaning and increasing flexibility in R&D and cGMP environments. These bags are equipped with ports (customizable) and optional optical sensors for pH/DO.

Suitability for Cell Cultures

OSBs are ideal for cell cultures, providing gentle mixing that ensures even nutrient and oxygen distribution, essential for the growth of human, animal, insect, plant, and stem cells.

Limitations for Microbial Work

OSBs are not suitable for microbial work, as bacteria and fungi require higher oxygen transfer rates and more vigorous mixing than OSBs can provide. However, for slow-growing species (doubling time comparable to cell cultures, approx. 20h) it may be worth a try.

Potential for Mixing Tasks

OSBs are useful for mixing tasks that require low shear stress, such as mixing sensitive biological materials like mRNA.

Application Examples in Various Industries

· Vaccines: Cultivation of insect cells to produce viral vaccines, like the COVID vaccine.

· Cellular agriculture: Cultivation of animal/plant cells for lab-grown meat or chocolate.

· Cosmetics: Cultivation of plant cells to produce bioactive compounds for skin care products.

· Cell and gene therapy: Cultivation of genetically modified cells for disease treatment or production of adeno-associated viral (AAV) vectors for gene therapy

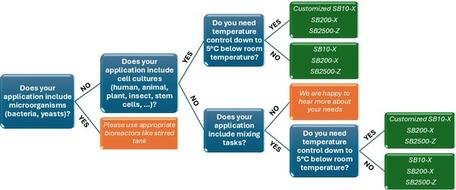

Decision Tree to Help You Find a Suitable Bioreactor for Your Application

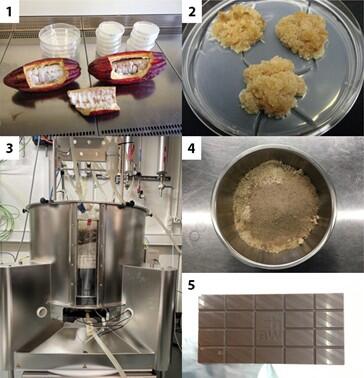

Follow the numbers to learn more about the workflow to produce lab-grown chocolate, using an orbital shaken bioreactor (SB200-X) for cell growth.

1) Isolation of cocoa cells from Theobroma cocoa.

2) Induction of callus formation.

3) Cell proliferation in SB200-X.

4) Post-harvest dried and grinded cocoa powder.

5) Final chocolate bar with special berry taste. Photos with kind permission by the ZHAW.

Further questions regarding your shaken culture?